The United States Graphite Company Specification Sheet Carbon, Graphite and Metal-Graphite Brushes

- Title

- The United States Graphite Company Specification Sheet Carbon, Graphite and Metal-Graphite Brushes

- Accession Number

- 2020.3.362

- Accession Date

- 25 June 2024

- Accession Creator

- Robert Martinez

- Depositor

- Bobby Barton

- Format

- Paper

- Storage Location

- Modernization Records Box Folder #11

- Text

-

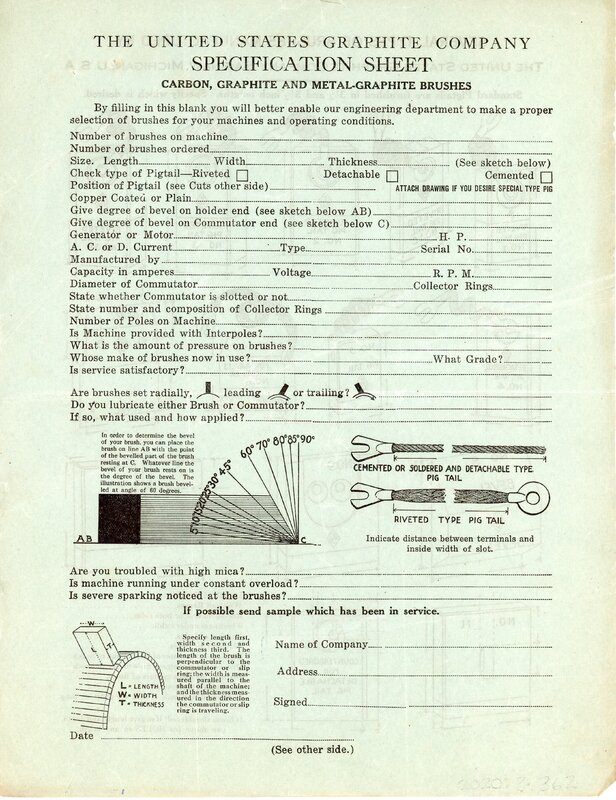

[Page One]

THE UNITED STATES GRAPHITE COMPANY

SPECIFICATIONS SHEET

CARBON, GRAPHITE AND METAL-GRAPHIE BRUSHES

By filling in this blank you will better enable our engineering department to make a proper

selection of brushes for your machines and operating conditions.

Number of brushes on machine

Number of brushes ordered

Size. Length Width Thickness (See sketch below)

Check type of Pigtail - Riveted [empty check box] Detachable [empty check box] Cemented [empty check box]

Position of Pigtail (see Cuts other side) ATTACH DRAWING IF YOU DESIRE SPECIAL TYPE PIG

Copper Coated or Plain

Give degree of bevel on holder end (see sketch below A B)

Give degree of bevel on Commutator end (see sketch below C)

Generator or Motor H. P.

A. C. or D. Current Type Serial No.

Manufactured by

Capacity in amperes Voltage Collector Rings

Diameter of Commutator Collector Rings

State whether Commutator is slotted or not

Number of Poles on Machine

Is Machine provided with Interpoles?

What is the amount of pressure on brushes?

Whose make of the brushes is now in use? What Grade?

Is service satisfactory?

Are brushes set radially ,[sketch of brush going straight up] leading [sketch of brush leaning, to the right] or trailing? [sketch of brush leaning to the left]

Do you lubricate either Brush or Commutator?

If so, what used and how applied?

in order to determine the level

of your brush, you can place the

brush on line AB with the point

of the bevelled part of the brush

resting at C. Whatever line the

bevel of your brush rests on is

the degree of the bevel-

led at angle of 60 degrees.

[sketch showing the angles of the bevel]

[Sketch of the soldered/detachable pig tail]

CEMENTED OR SOLDERED AND DETACHABLE TYPE

PIG TAIL

[Sketch of the riveted pig tail]

RIVETED TYPE PIG TAIL

Indicate distance between terminals and inside width of slot

Are you troubled with high mica?

Is machine running under constant overload?

Is severe sparking noticed at the brushes?

If possible send sample which has been in service

[Close up sketch of the brush]

L = LENGTH

W = WIDTH

T = THICKNESS

Specify length first,

width second and

thickness third. The

length of the brush is

perpendicular to the

commutator or slip

ring; the width is meas-

ured parallel to the

shaft of the machine;

and the thickness meas-

ured in the direction

the commutator or slip

ring is traveling.

Name of Company

Address

Signed

Date

(See other side.)

[END OF PAGE ONE]

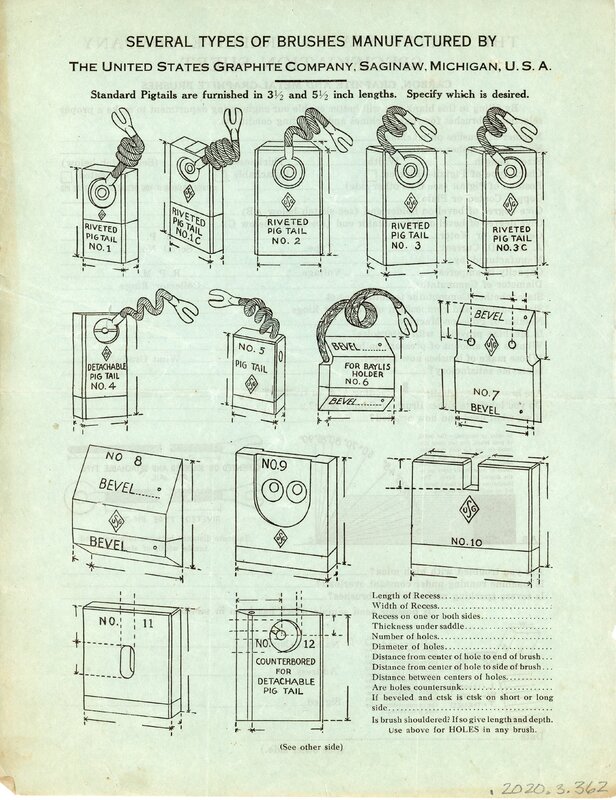

[Page two]

SEVERAL TYPES OF BRUSHES MANUFACTURED BY

THE UNITED STATES GRAPHITE COMPANY, SAGINAW, MICHIGAN, U.S.A.

Standard Pigtails are furnished in 3 1/2 and 5 1/2 inch lengths. Specify which is desired.

[Drawings of the different kinds of pigtails]

Length of Recess

Width of Recess

Recess on one or both sides

Thickness under saddle

Number of holes

Distance from center of hole to end of brush

Distance from center of hole to side of brush

Distant between centers of holes

Are holes countersunk

If beveled and ctsk is ctsk on short or long side

Is brush shouldered? If so give length and depth.

Use above HOLES in any brush.

[END OF PAGE TWO]

Part of The United States Graphite Company Specification Sheet Carbon, Graphite and Metal-Graphite Brushes